Table of Contents

Modern wine dispensing systems provide an elegant solution for serving wine by the glass while maintaining freshness. These advanced devices chill bottles to perfect serving temperatures and protect the wine from oxygen exposure during each pour. The contamination-free environment preserves the wine’s delicate flavors and aromas, allowing bars and restaurants to offer premium wine service without worrying about spoilage or waste. With precise portion control, these systems prevent over-pouring while ensuring guests receive perfectly measured servings every time. Discover how wine dispensers keep every glass fresh and perfectly measured. This article examines how an automated winestation combines advanced preservation, temperature control and precision pouring technology for both commercial and home use.

How WineStation dispensers preserve wine automatically

An automated wine station merges sophisticated dispensing technology with airtight protection to keep opened bottles in pristine condition. The dispenser system creates a barrier against oxidation while its calibrated mechanism delivers perfectly measured pours throughout extended wine service periods.

Genesis preservation technology with inert gas injection

The genesis preservation and wine dispensing system utilizes food-grade nitrogen or ultra-pure argon to create an oxygen-free environment after each pour. This cutting-edge wine dispensing technology instantly replaces headspace air, stopping oxidation that would otherwise compromise aromas and flavors. Bar staff simply need to touch the intuitive control panel to activate this fully automated protection system.

- Extended freshness with argon: Being denser than nitrogen, argon preserves wine for up to 60 days.

- Cost-effective nitrogen option: While protecting wine for about three weeks, nitrogen offers lower operational costs, making it ideal for high-volume establishments.

- Advanced vacuum sealing: An optional vacuum function reduces headspace oxygen to less than 0.5%, meeting NSF and EU 1935/2004 safety standards.

- Complete humidity management: Integrated humidity control preserves corks while internal circulation ensures even gas distribution throughout the wine dispensing system.

Built-in sensors continuously monitor gas levels, automatically activating when oxygen exceeds preset limits. This allows staff to focus on wine service without manual inspections, as the system maintains ideal conditions throughout operations at the station.

Dual-zone temperature control for red and white wines

Advanced thermo-electric technology creates two independent climate zones within a single winestation unit. Whites are maintained at a crisp 10-14°C while reds are kept at the optimal 15-18°C – eliminating the need for separate cooling units and saving valuable space.

The system’s proactive temperature control maintains each varietal’s perfect serving conditions regardless of frequent access or kitchen heat. Smart sensors make instant adjustments to guarantee every pour reaches the glass at its ideal temperature.

Precision pourer mechanisms with calibrated flow sensors

Four hygienic pouring heads deliver contamination-free servings with customizable volumes ranging from small 0.25 oz tastings to generous 9 oz glasses. Sophisticated flow sensors automatically adjust for different bottle sizes and wine viscosities, ensuring accurate measurements whether pouring from half-bottles or magnums.

Busy establishments can serve up to 120 glasses hourly, with the standard 12 cl pour completing in approximately six seconds. Quick-change bottle mechanisms allow for sanitary touch-free swaps in under ten seconds, maintaining seamless wine dispensing service.

Commercial benefits of automated wine station systems

Automated wine dispensing technology transforms beverage profitability for bars through precise inventory management and reduced waste. The system’s accurate portion control ensures each pour contributes to higher margins, while advanced preservation keeps premium red wines fresh much longer than traditional methods.

Reducing waste and increasing profitability with portion control

The wine dispenser system eliminates costly over-pouring with its precise flow measurement, while the optional Coravin wine aerator allows bars to safely offer premium selections by the glass. This combination of dispensing technology and preservation gives wine bars confidence to stock higher-end bottles without concerns about spoilage.

With bottles staying fresh longer, wine stations typically see sales increase by 15-25% as reduced waste combines with the ability to charge premium prices for rare vintages by the glass, encouraging customers to explore new options.

| Waste Reduction Method | Savings Percentage | Implementation Timeframe |

| Automated portion control | 25-40% | Immediate upon installation |

| Extended preservation (argon) | 15-20% | Within first service quarter |

| Theft prevention via access control | 10-15% | 2-4 weeks staff adaptation |

The integrated access control system tracks every pour with user authentication, creating complete accountability. Managers can restrict access to premium inventory, preventing unauthorized dispensing and reducing loss.

Real-time analytics and POS integration for inventory tracking

Every automated wine station connects directly to your POS system, eliminating manual inventory counts in your hospitality business. The software records precise details of each pour – volume, staff member, and time – providing a perfect audit trail.

- Sales dashboard insights: Clear visual reports highlight top-selling reds, busiest times, and average pour sizes to optimize promotions.

- Margin optimization data: Instant cost analysis identifies underperforming wines, allowing quick menu adjustments to maximize profits.

- Predictive ordering algorithms: Smart consumption tracking automatically triggers reorders before you run low during peak hours.

By matching physical stock with sales data in real time, the dispensing system reduces labor costs and improves profit calculations. This wine dispensing technology delivers concrete benefits that elevate modern bar operations.

Guest experience and nitrogen preservation in touch-enabled stations

Modern interactive wine stations transform ordinary wine service into an engaging, self-service experience. Guests simply tap their smart card, select their preferred wine, and enjoy a perfectly measured pour protected by advanced nitrogen technology. This contamination-free dispensing system allows customers to explore freely while maintaining impeccable wine quality and precise portion control.

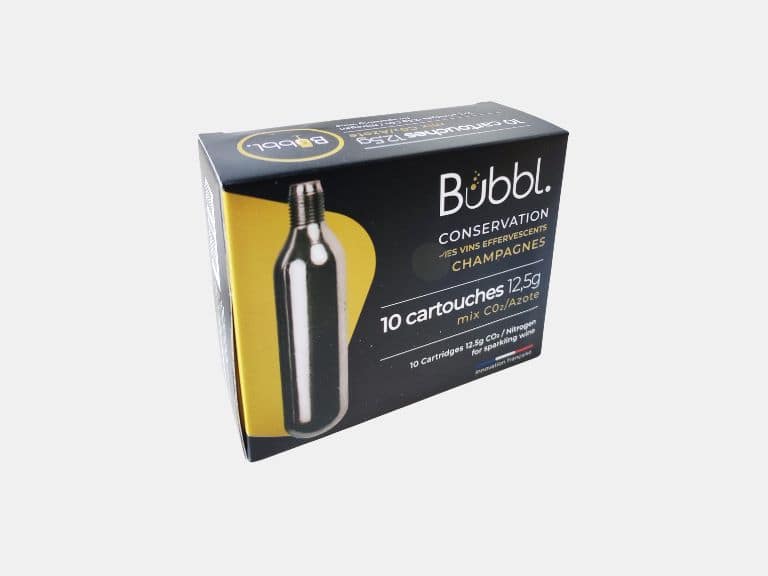

Nitrogen wine preservation systems work by creating an inert gas barrier that pushes out oxygen, preventing oxidation while preserving the wine’s aroma. The system delivers a precise gas burst before sealing the bottle airtight, keeping even a full glass fresh for multiple days. Options range from compact cartridges for busy bar setups to bulk generators for large venues, with special CO₂-N₂ blends specifically designed to maintain Champagne’s bubbly character. Learn how nitrogen dispensers guarantee fresh pours every time

Interactive self-serve features with smart-card technology

Using smart-card or QR verification, customers can select red or white wines, customize pour sizes, and enjoy contamination-free wine without any staff interaction. Vibrant digital displays showcase tasting notes and pairing suggestions, encouraging exploration while boosting sales. Locations equipped with coravin capsules stores can further enhance their wine station versatility.

- Custom tasting flights: Pre-programmed sampling journeys guide guests through curated selections, increasing sales while educating palates.

- Personalized recommendations: The system tracks past choices and suggests new wines aligned with individual preferences.

- Promotional opportunities: Screens highlight limited-time offers on new arrivals, creating incentives to try premium selections.

- Signature experience: Sleek, touch-free interfaces create memorable brand moments that differentiate from traditional service.

Integrated data tracking feeds into loyalty programs, converting occasional visitors into regulars. Guests return for both the innovative technology and dependable, contamination-free wine quality.

Choosing nitrogen or argon for different service environments

High-volume bars serving 50-100 daily glasses benefit from nitrogen systems that preserve bottles for 3-7 days. Boutique establishments with slower turnover may prefer argon for extended freshness up to four weeks, justifying premium pricing for rare vintages at their station.

For sparkling wines, use special CO₂-N₂ blends with pressure-controlled caps. This 80/20 combination preserves bubbles while preventing oxidation, keeping Champagne fresh with full effervescence for about a week after opening.

Maintenance requirements for gas-based preservation systems

Regular maintenance ensures contamination-free operation and prolongs equipment lifespan. A structured schedule minimizes downtime while meeting health regulations for beverage equipment.

- Safe cartridge disposal: Always depressurize spent cartridges before recycling for safety compliance.

- Cap hygiene: Clean reusable seals with warm, soapy water after each use to maintain airtight performance.

- System calibration: Quarterly checks of flow meters and regulators guarantee accurate pouring and portion control.

- Usage tracking: Document gas replacement dates and consumption patterns to optimize supply management.

Automated cleaning cycles sanitize pouring lines in under three minutes without manual contact. Built-in diagnostics alert staff to potential issues before they affect operations, ensuring uninterrupted wine service.

Frequently Asked Questions

How long does wine last in a dispenser?

An automated wine dispensing system keeps open bottles fresh through a combination of inert gas and temperature control. The longevity depends on your setup—in busy bars using nitrogen, wine stays good for 3-7 days, while in slower-paced venues with argon gas, a winestation can preserve reds and whites for up to 60 days.

For sparkling wines, a CO₂–N₂ blend maintains carbonation for about a week. Modern wine preservation systems like the WineStation use vacuum extraction and precise oxygen monitoring to ensure every pouring session delivers a clean pour, keeping oxygen levels below 0.5% for optimal quality.

What is the best commercial wine dispensing system?

The ideal wine dispensing system balances preservation technology, pouring accuracy, and temperature control. Many professionals prefer the WineStation for its four independent dispensing heads, dual-zone cooling, and RFID access control—key features that minimize waste and streamline service.

High-traffic locations often opt for bulk-nitrogen wine dispensers with usage tracking, while a wine bar prioritizing extended bottle life might choose argon-based preservation systems. The best choice depends on your daily volume, available space, and whether self-serve or staff-assisted wine serving suits your operation.

How much does a WineStation dispenser cost?

Pricing for a wine station dispenser varies by capacity and features. A compact four-bottle unit designed for smaller bars starts at a mid-range price, while larger eight-bottle systems with advanced temperature control and analytics command a premium.

For extensive installations handling 80+ bottles—often integrated with cellar storage—the investment is higher, but the gains in wine preservation and reduced waste typically lead to ROI within 18-24 months. Don’t forget to factor in ongoing costs like argon or nitrogen gas, maintenance, and POS compatibility when budgeting for your wine dispenser machine.