The perfect wine cellar humidity ranges between 55–70% relative humidity – keeping corks properly sealed, labels pristine, and preventing mold growth. This guide explains how humidity interacts with wine cellar temperature, the consequences of fluctuations, and practical solutions for maintaining ideal conditions. Discover the optimal humidity level for your cellar setup, reliable ways to monitor moisture levels, and simple adjustments for your humidifier or dehumidifier to ensure flawless aging.

Optimal wine cellar humidity for wine storage

You’ll want to maintain a consistent 55–70% relative humidity in your wine cellar, with 60–65% being the sweet spot for most collections. This range keeps natural corks supple while preventing mold or label damage. Consistency is key – while brief deviations won’t cause lasting harm, constant swings in humidity can weaken corks and packaging materials over time.

When cellar humidity drops below 50%, corks dry out and shrink, allowing oxygen to creep in – flattening flavors even if your cellar cooling keeps temperatures perfect. Conversely, levels above 75–80% create ideal conditions for mold to grow on labels, cork tops, and wooden racks. These conditions can also weaken adhesives and allow musty odors to penetrate older bottle closures.

Why 55–70% RH protects wine cellar corks

Natural cork closures rely on stable humidity to maintain their sealing properties. Maintaining 60–65% relative humidity keeps corks properly expanded, limiting oxygen exchange to about 1mg per year – the ideal rate for controlled aging. This delicate balance allows wine to develop complexity at just the right pace.

- Perfect cork seal: At 55–70% RH, corks maintain their elasticity, ensuring a tight fit that prevents air leaks during long-term wine storage.

- Controlled aging: Stable humidity enables just enough oxygen exchange to develop bouquet and soften tannins, while extreme conditions disrupt this natural process.

- Evaporation control: Proper moisture levels minimize evaporation, preserving fill levels and preventing premature aging signs like rising ullage.

Older corks are particularly vulnerable to low humidity. Years of compression reduce their natural resilience, and just a few months below 50% RH can cause cracking or shrinkage in vintage closures. While slightly moist conditions are generally safer than dryness, always ensure humidity stays below the mold threshold and monitor labels for any adhesive issues.

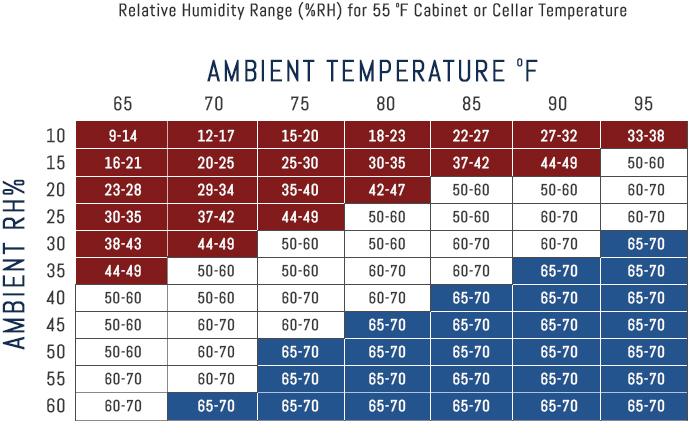

Humidity and temperature pairing for wine storage

The classic wine cellar temperature of 12–14°C (55–57°F) paired with 60–65% relative humidity creates ideal aging conditions. Cooler air naturally holds less moisture, so maintaining a stable low temperature helps regulate RH when proper insulation is in place. However, if temperatures rise without additional moisture, relative humidity drops sharply – while warm, humid air entering a cooled space can cause RH spikes and condensation.

Remember: no level of humidity control can compensate for excessive heat, which accelerates chemical reactions that deteriorate wine quality. Similarly, perfect 12°C temperatures with 35% RH will still dry out corks and spoil wine just as effectively as poor cooling. Effective wine storage requires managing both parameters through proper insulation, vapor barriers, and well-sealed doors.

Dual-zone cellars present added complexity – while you might store whites at 7–10°C and reds at 14–16°C, each zone still needs 55–70% RH. Temperature fluctuations overnight can alter relative humidity and cause condensation without proper humidity control. Opt for units with built-in humidistats or passive reservoirs, and always place hygrometers in each compartment to verify conditions regularly.

How stability preserves labels and provenance

Stable humidity isn’t just about protecting the wine – it also safeguards your labels that document a bottle’s origin and vintage. When RH constantly swings between 40% and 80%, adhesives fail, paper warps, and inks can run or fade – potentially destroying a bottle’s provenance even when the wine inside remains perfect.

Aim for a narrow, stable humidity range rather than chasing an exact number. Gradual seasonal changes are far safer than daily spikes that stress packaging materials. Install digital hygrometers at bottle level (away from doors and vents) to monitor trends and adjust your humidifier or dehumidifier proactively. Consider data loggers and remote alerts to catch problems early when you’re away from your collection.

Controlling wine cellar humidity for wine storage

Proper wine cellar humidity control starts by understanding what causes humidity to rise or fall from the ideal range. Once diagnosed, we balance structural elements with active systems to maintain consistent cellar humidity year-round. Whether you store wine in a dedicated room, built-in unit, or standalone cooler, these strategies ensure optimal aging conditions for your collection.

What causes high or low wine cellar humidity

Low humidity often results from excessive AC operation removing moisture, or compromised door seals allowing dry air to enter. Inadequate vapor barriers, frequent access, arid climates, and heating systems can also reduce cellar humidity below safe levels. When levels stay below 50% for extended periods, you’ll notice increased evaporation through corks, leading to flavor degradation.

High humidity occurs when moisture inflow exceeds dehumidification capacity – common in basements or tropical areas. Warm, moist air penetrates through unsealed walls, condensing on cool bottles and pushing RH above 75%. Persistent dampness promotes mold growth on labels, corks, and wooden cellar components without proper ventilation and sealing.

Practical methods to raise or lower humidity

To increase humidity, we recommend humidity-controlled ultrasonic or evaporative humidifiers activated when RH drops below 60%. Walk-in cellars benefit from systems integrated with cooling airflow, while smaller units can use compact humidifiers or simple water trays. Basic moisture solutions like damp sponges gently elevate levels in moderately dry conditions.

Reducing humidity requires dehumidifiers programmed for RH levels above 65-70%. Sealing potential entry points prevents moist air intrusion, while proper vapor barriers minimize condensation that contributes to high humidity. Efficient cooling systems with proper drainage, combined with well-timed ventilation, effectively manage excess moisture without energy waste.

| Method | Effect on RH | Best application |

| Ultrasonic humidifier with humidistat | Raises RH 10–20 points | Dry climates, walk-in cellars, cabinets below 50% RH |

| Evaporative humidifier | Raises RH 5–15 points | Medium-dry spaces, integrates with cooling airflow |

| Passive water trays or sponges | Raises RH 2–5 points | Small cabinets, mild dryness, minimal maintenance |

| Dehumidifier with humidistat | Lowers RH 10–25 points | Coastal/tropical basements, spaces above 75% RH |

| Improved sealing and vapor barriers | Stabilizes RH ±5 points | All cellars, reduces active equipment workload |

| Ventilation with exhaust fan | Lowers RH 5–10 points | Damp basements, prevents stagnant moist air |

Monitoring tools and maintenance routines

Install multiple digital hygrometers at different rack levels to accurately track wine cellar humidity and temperature. While analog hygrometers can serve as backups, they require regular calibration. Recording weekly readings helps identify patterns, while sudden changes may indicate equipment issues or unintended access.

Conduct quarterly door seal inspections and monthly cleaning of humidifier components to prevent mold. Annual structural checks ensure no new air leaks develop, and proper bottle orientation maintains cork hydration. Address early signs of moisture problems by adjusting RH levels before mold becomes established.

Diagnose issues through observable clues: low humidity shows as receding wine levels; high humidity causes label damage. Musty odors confirm excessive dampness, while monitoring data helps correlate these symptoms with external conditions. This proactive approach guarantees ideal aging conditions for your valuable vintages.

Wine cellar design choices for stable wine storage

The materials you choose for construction and wine cellar design directly impact your ability to maintain consistent temperature and humidity levels over time. Whether you opt for wood, stone, metal framing, or different insulation types, each affects moisture retention, thermal stability, and climate control demands. Selecting the right combination for your location helps create a self-regulating environment that protects corks, labels, and overall wine quality with minimal effort.

Materials that stabilize a wine cellar climate

Wooden wine racks naturally moderate humidity fluctuations by absorbing and releasing moisture, reducing how often your humidifier runs. To prevent mold or warping while maintaining wine storage integrity, we recommend sealing pine, cedar, or oak with non-toxic, water-based finishes. With proper annual maintenance, these wine storage materials offer the perfect balance of functionality, visual appeal, and long-term aging performance.

- Wood racks : Excellent humidity buffering and classic aesthetics; require sealing in high-humidity environments but work beautifully for home wine cellars maintaining 55-70% RH.

- Stone and masonry : Provides exceptional thermal mass for temperature and humidity stability, often reducing mechanical climate control needs. Perfect for underground cellars designed for extended aging.

- Closed-cell spray foam with vapor barrier : Creates an impenetrable moisture barrier (R-6–R-7 per inch) but typically requires supplemental humidification in dry climates to prevent overly low RH and condensation issues.

- Metal framing with continuous insulation : Offers durability and fire resistance, though proper insulation and vapor barriers are crucial to prevent thermal bridging. A favorite for commercial wine storage facilities.

Natural stone or masonry walls excel at absorbing temperature shifts and maintaining moisture levels, often keeping wine cellar humidity within ideal ranges without constant equipment intervention. While underground spaces benefit most, proper waterproofing is essential to prevent humidity from exceeding 80% and causing mold. Above-ground cellars can achieve similar stability using stone veneer over high-performance insulation and vapor barriers.

Sealing, insulation and vapor barriers that work

Creating a reliable wine cellar starts with comprehensive sealing. We ensure perfection by:

- Installing tight door weather stripping

- Sealing all utility penetrations

- Adding threshold sweeps

- Applying six-mil poly or foil-faced insulation on climate-appropriate wall surfaces

This prevents condensation issues that could damage corks or racks. Insulation requirements vary by region—typically R-19–R-30 for walls and R-38–R-50 for ceilings. Closed-cell foam is ideal as it provides both insulation and vapor control. Continuous insulation over metal studs eliminates cold spots, while any gaps risk humidity problems and equipment strain. A final blower-door test verifies system integrity before installing racks, ensuring your cooling unit can maintain perfect conditions efficiently.

Regional and cabinet-specific humidity strategies

In arid regions like the American Southwest or inland Australia, ultrasonic humidifiers become essential to raise cellar humidity from desert-dry 25–35% to wine-friendly 60–70%. Achieving this requires:

- Meticulous sealing

- Premium insulation

- Use of distilled water to prevent mineral buildup

Coastal and tropical areas face the opposite challenge, where ambient humidity often sits at 75–90%. These cellars need:

- Powerful dehumidification

- Strategic ventilation

- Regular cleaning to prevent mold on racks, labels, and corks

For freestanding units and under-counter cabinets that dehumidify during cooling, passive humidification solutions maintain optimal 55–60% RH. Dual-zone systems manage humidity independently for different temperature zones, though we often supplement with ultrasonic cartridges for precision control. Large aging cellars benefit from professional monitoring systems that track temperature, wine cellar humidity, and airflow while sending alerts for any deviations.